Talk about CNC CNC machining center machining accuracy grade

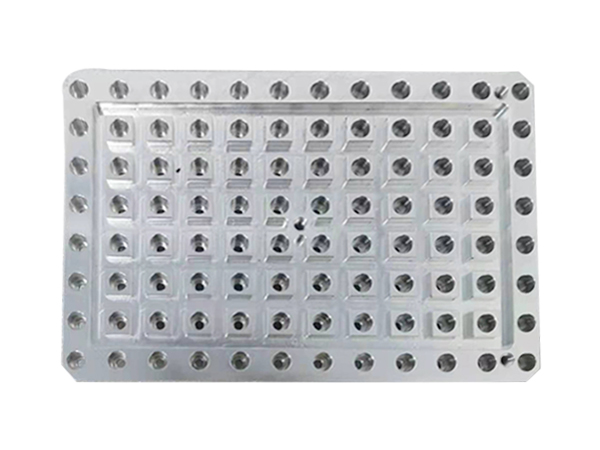

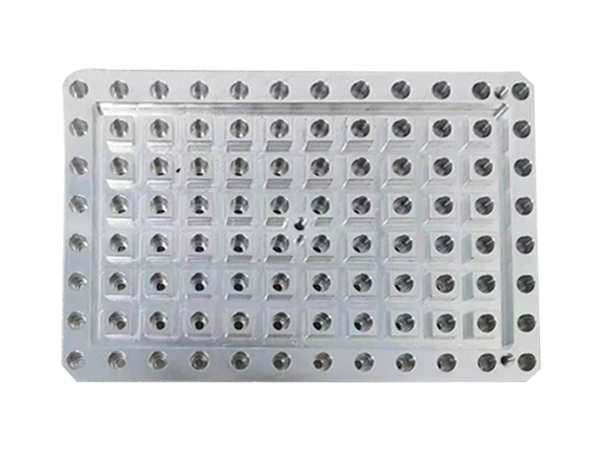

Dongguan Lifei Precision Machinery & Mould Co., Ltd. was established in December 2015. It is a machinery parts factory that produces, processes machinery parts, processes precision parts and provides assembly services. It supports the processing of all kinds of fixture and precision machinery parts. The company has production equipment such as high-speed CNC machining centers, CNC lathes, lathes, milling machines, grinding machines, wire cutting. And a number of sophisticated inspection equipment, such as microscope, projector, hardness tester, Swiss height meter, three-dimensional, etc., to meet customer product production and processing and quality inspection needs. Many friends who understand CNC processing industry know that the precision degree of CNC processing has grade division. Next, Lifei will take you to understand the grade division of CNC processing.

In general, according to the division of the international precision tolerance class, IT6 is widely used in machining important fit index. IT6 means with the surface has a higher uniformity requirements, can ensure quite high with the property, the use of stable and reliable, machining center can complete drilling, milling, boring, expanding, reaming, rigid tapping and other processes processing.

A, drilling

Drilling is another important processing process processing center, drilling is a basic method of hole processing, drilling is often carried out on the drilling machine and lathe, some high precision requirements can also be completed in the processing center.

The machining accuracy of drilling is low, the tolerance grade can only reach IT10, and the workpiece surface roughness is generally 12.5 -- 6.3μm, but after drilling is completed, reaming and reaming are often used to carry out subsequent semi-finishing and finishing.

Milling is the most important machining process of the machining center, it can be said that all the machining process of the machining center is expanded through milling. Milling is divided into reverse milling and down milling according to the direction of spindle movement and workpiece feed. It is an efficient and common machining method in machining center to use rotating multi-edge tool to cut workpiece. Suitable for machining plane, groove, all kinds of complicated different surface and surface mold and other special surface.

The tolerance level of precision milling in milling is generally up to IT16 -- IT8, and the surface roughness of the workpiece is 0.63 -- 5μm under the processing standard of this tolerance accuracy.

C, boring

Boring is generally used for the machining of the inner diameter part. A machining process in which a cutter is used to enlarge a hole or cut the inner diameter of a circular outline, generally from semi-rough to finish. The tolerance grade of boring precision for steel workpiece is IT9 -- IT7, and the surface roughness is 2.5 -- 0.16μm. < BR > Current machining processes require the highest accuracy and lowest tolerance levels of grinding. And stamping and die casting tolerance level teach high, understand the precision tolerance of each process we can let the CNC machining center play the characteristics of high precision. Different products in different industries have different precision levels. As practitioners and manufacturers, they should understand and pay attention to the actual needs of users' products. For example, medical and auto parts have relatively high requirements for precision, while exterior components have relatively low requirements for precision.

Website QR code

Website QR code Wechat QR Code

Wechat QR Code