share

CNC precision machiningWhat are the material requirements?

Precision machining technology refers to the processing technology whose machining accuracy and surface smoothness are higher than those of the corresponding processing methods.

There must be a lot of matters will pay attention to in the processing, there will be a lot of factors affecting the quality of the product, so we must pay attention to some details of the above problems, so let's understand the requirements of precision processing for the material?

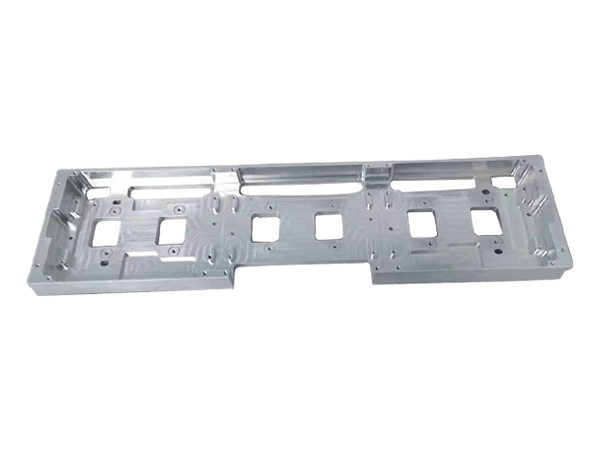

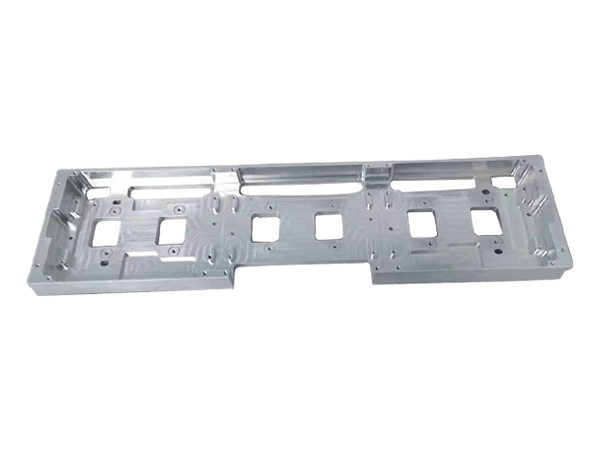

Precision machining

1. First of all, the hardness of the material is required. For some occasions, the higher the hardness of the material, the better, but limited to the hardness requirements of the processing machine, the processing material can not be too hard, if it is harder than the machine is unable to process.

2. Secondly, the material is moderate soft and hard, at least one grade lower than the hardness of the machine, but also depends on the role of the processing of the device is to do what to use, reasonable material selection of the machine.

In short, there are still some requirements for precision mechanical processing of materials, and not what materials are suitable for processing, such as too soft or too hard materials, the former is not necessary for processing, and the latter is unable to process.

Therefore, the most basic one is that before processing, we must pay attention to the density of the material, if the density is too large, equivalent to the hardness is also very large, and if the hardness exceeds the hardness of the parts (lathe tool), it can not be processed, not only will damage the parts, but also cause danger, such as the tool flying out of wounding. Therefore, generally speaking, for mechanical processing, the material material should be lower than the hardness of the machine knife, so as to be processed.

Website QR code

Website QR code Wechat QR Code

Wechat QR Code