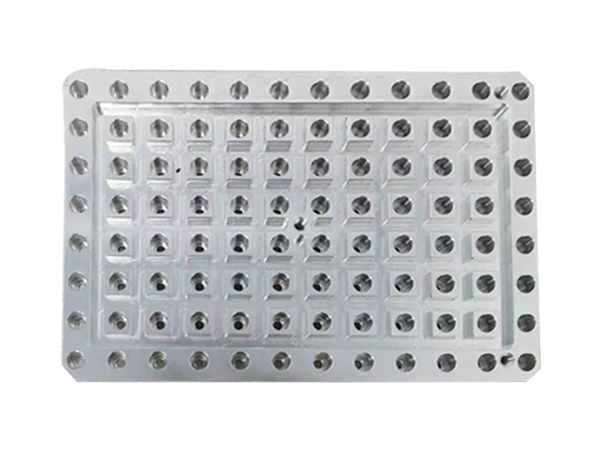

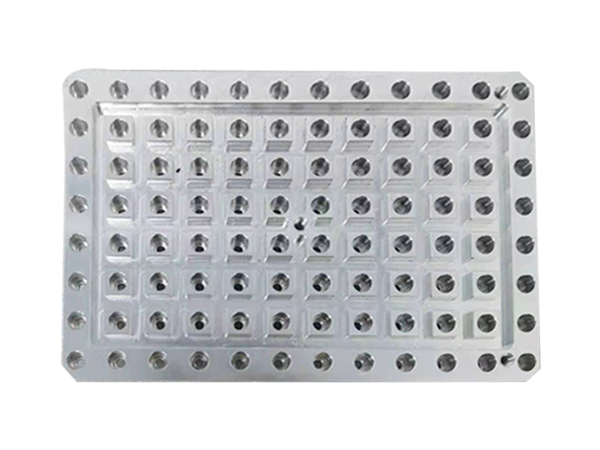

CNC machining process involves tool selection, cutting parameters and tool path. CNC machining technology is the core of NC programming. Select processing time less, the smallest tool path of the NUMERICAL control program, to achieve high efficiency and high quality products. CNC processing technology can be divided into rough machining, clear Angle, finishing.

The advantages of doing this are: first, it is convenient for the grinder to grind the shaft quickly back to the sand wheel, and it will not grind to the end face and affect the length. Second, when assembling, it completely touches the end face, and the end face runout will be smaller. < P > Dongguan Lifei Precision Machinery & Mould Co., LTD., established in December 2015, is a mechanical parts factory engaged in manufacturing and assembly services, supporting the processing of all kinds of fixture and precision machinery parts. Currently, there are several process engineers and technical personnel. The company has production equipment such as high-speed CNC machining centers, CNC lathes, lathes, milling machines, grinding machines, wire cutting. And a number of sophisticated inspection equipment, such as microscope, projector, hardness tester, Swiss height meter, three-dimensional, etc., to meet customer product production and processing and quality inspection needs.

About us

Company profileCulture EnvironmentDetectionContact usProduct Center

Medical parts processingLaser parts processing Semiconductor parts processingLithium battery accessories processing Electronic parts processing view moreApplication field

Medical device industryLaser equipment industrySemiconductor industryRobot spare parts applicationMarine spare parts industryNews center

company dynamicIndustry dynamicFAQScan the QR code

Website QR code

Website QR code Wechat QR Code

Wechat QR Code